30 plus students in your class? Not getting the specific guidance you need? I provide personalised support for AS and A Levels, and cover all the boards inc. WJEC, Edexcel, AQA, OCR and Cambridge International. Each student is assessed on an individual basis so any generic advice I publish here may not be suitable for your particular circumstance.

However, below are some of the practical exercises that I usually complete with my Sixth Form. These can usually be achieved with hand tools and minimum equipment (apart from a Centre Lathe and Brazing Hearth!).

Developing Competencies:

1. Fabricating a Mild Steel Component

A basic engineering exercise using:

- Rectangular piece of mild steel 1-1.5mm thick

- Steel Ruler

- Scribe

- Engineers’ Blue

- Engineers’ (Tri) Square

- Calipers / Odd Leg Calipers

- Metal Files

- Hacksaw (HSS blades)

- Drills

- Engineers Vice

- Centre Punch (Metal)

- Emory Paper

- Wet & Dry paper

Interpret and accurately transfer an engineering drawing to a piece of mild steel plate and then cut it out using appropriate hand tools and wasting techniques.

Choose your exercise:

- Skill Test 1

- Skill Test 2

- Skill Test 3

- Skill Test 4

- Skill Test 5

- Skill Test 6

- Skill Test 7

- Skill Test 8

- Skill Test 9

- Skill Test 10

A basic engineering exercise: interpret and accurately transfer an engineering drawing to a piece of Aluminium round bar using a Cenre Lathe.

3. Screwdriver

- Appropriate length Mild Steel Hexagonal Bar for screwdriver handle.

- Centre Lathe – shaping the screwdriver handle using different tools – form turning and taper turning.

- Appropriate length Silver Steel Rod (5mm) – Air Hardened Silver Steel contains the highest alloy content making it hard and resistant. It is commonly used to create specialized tools including gauges, punches, and shears.

- Hearth – for Forging screwdriver blade and for Hardening and Annealing.

- Oil bath for Hardening and Annealing process.

- Anvil and Hammers – for forging and shaping the screwdriver blade.

- Metal Files – for shaping the screwdriver blade.

- Emory Cloth and Wet & Dry paper – cleaning and polishing.

- Tap – Cutting the internal thread in the screwdriver handle.

- Die – Cutting the external thread into the screwdriver blade.

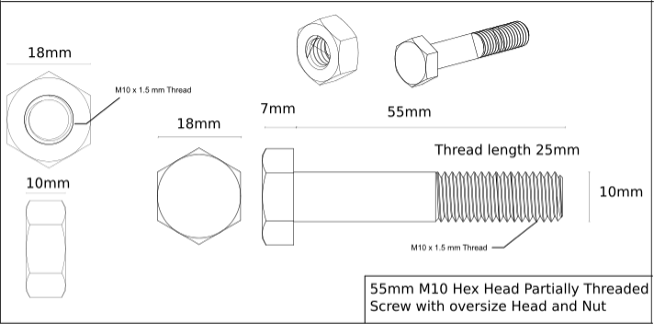

Another basic engineering exercise: interpret and accurately transfer an engineering drawing to a piece of Aluminium hex bar and then make a blank nut and bolt using appropriate techniques.

A basic engineering exercise: adding internal and external threads to the blank nut and bolt made in the previous exercise

5. Bossing & Planishing Copper PPT

6. Hand Riveting, Pop Rivetting & Mechanical joining methods

7. Sand Casting a G-clamp

8. Resource Files

- Health & Safety in Schools: BS41632007

- Y12 Developing Competencies – LATHE

- Risk Assessment:_MW01_metalwork_centre_lathe_BLANK

- Y12 Annealing Metal

- Y12 Forming Metal

- HW Metal 1