A

Access FM (PDF)

Additive & Subtractive Manufacturing Processes

Amps & Volts (YouTube)

Anthropometrics (Web)

Artistic Movements/Designers – Movement Summary Cards (PDF)

AQA A Level Design and Technology –Introduction to the course (L1)

B

Brainstorm (or Free Association):

Free association. What this means is that we have a web of memories that are connected based on related features. Through this, seemingly distant concepts can become connected to each other. For example, seeing a pineapple in the grocery store might remind you of Hawaii which then reminds you of a past vacation with family, and suddenly you’re feeling nostalgic for that relaxing time. See the figure below for what this web of free associations looks like. These connections take you in unexpected directions and make unexpected/original connections. A powerful tool for ideation!

Bolts (US and Metric Thread Sizes)

Butt Hinges (How to install them…)

C

- Centre Lathe – Facing Off

- Centre Lathe – Parallel Turning

- Centre Lathe – Taper Turning

- Centre Lathe – Knurling

- Centre Lathe – Parting Off

D

De Stijl (BING)

Design Movements – Art History (PDF 6Mb)

Design-Movements-Timeline (PDF)

Digital_Manufacturing_For_Dummies_UK (PDF)

E

Edexcel A Level Product Design – new 2020 content in the exam spec. but not in the 2008 text book!

Examples of GCSE Coursework

Dubai British School

- A* Product Design (Slideshare)

- A* Product Design (Slideshare)

F

Fasteners (This superb printable PDF guide will help you identify fastener categories, head styles and drive types, as well as common nut, washer types and threads. )

G

GCSE Resistant Materials Exam Questions (Good for revision)

H

Hardening – Hardening steel involves heating it up to a particular temperature and then rapidly quenching it in water, oil, or whatever medium is appropriate for the specific alloy. However, the steel has to have sufficient carbon content for it to harden. Depending on the application, the hardening process frequently leaves the steel too hard-similar to a piece of glass. So the tempering process is used to “take out” some of the hardness, leaving it hard enough for its intended purpose but with enough ductility to be tough. Obviously, this is a very simplified description of the process but I think you get the idea.

Steel changes colours at different temperatures. So you can see how hot the steel is by carefully watching its colour as you heat it. Once it reaches the correct temperature, quenched it in oil or water (oil is the proper quenching medium for spring steel). Keep it completely submerged in the oil, and swirl it around in the oil until it cools off. Then remove it and clean it off for the next step: tempering.

I will add a detailed explanation asap.

I

J

Jig – is a device that allows you to repeat procedures accurately – this could be cutting or drilling or even folding. In this case this is a professionally made jig for the drilling of Kitchen door hinges:

• Preps doors for 35mm Hinge Cups and 8mm screw holes

• For drilling holes for hinges with either screw fixing or pre-mounted euro screws

• With template for wing mounting plate

• Bit for hand drill machine

• 2 x drill Ø 8 mm

• 1 x drill Ø 35 mm

• Bit for boring machine

So this jig (using a portable electric hand drill) allows you to drill holes for two screws and bore a hole for a recessed spring mechanism, over and over again. Of course you can make much simpler jigs to help you drill holes accurately in your work with just a couple of bits of scrap wood.

So this jig (using a portable electric hand drill) allows you to drill holes for two screws and bore a hole for a recessed spring mechanism, over and over again. Of course you can make much simpler jigs to help you drill holes accurately in your work with just a couple of bits of scrap wood.

K

L

M

Materials (Prezi)

Materials (L2) (Everything you need to know!)

Memphis (BING)

Metals Revision Sheet (PPT)

N

Nuts & Bolts (PDF)

Nuts, Bolts & Spanners

O

P

Packaging (Cherry Lock)

Phillipe Starck (BING)

Press Kit – for a charity / NGO

Printing (Digital vs Offset)

Printing (Intaglio)

Printing (Lithographic)

Printing (Offset litho)

Printing (Gravure)

Printing (Litho vs Gravure)

A quick look at the key feature, process and benefit differences of Gravure and Web Offset printing:

- The gravure printing process has the ability to print a smoother image and more consistently on lightweight papers.

- Web offset printing presses have fixed cylinder cutoffs, whereas gravure presses have a variable cutoff dictated by the cylinder diameter used.

- Web offset dots are printed as a round dot; gravure ones are hexagonal.

- Web offset uses a printing plate; gravure a cylinder engraved with cells which carry ink.

- Web offset is an offset printing process, whereas gravure is intaglio (i.e. the cylinder comes into direct contact with the paper and is not offset).

- Web offset inks are dried by heat from a gas oven. Gravure inks contain a solvent called Toluene which, as well as being toxic, evaporates, hence drying the ink without heat.

- Web offset presses can print either long or short grain; gravure prints short grain, due to folder configurations.

- Web offset printing is suitable for 8pp A4 sections upwards from runs of 50,000 upwards. Normally gravure will print sections from 8pp to 168pp in size and is competitive for runs, usually, from several hundred thousand to millions of copies.

- Web offset plates will run for around a million impressions; gravure cylinders, which are coated in chrome, can last for over 20 million impressions.

- The set-up costs of a gravure press are several times that of a Web offset printing press – hence the size of run needed for the process to be competitive.

Printing (Web vs Sheet)

Printing (CMYK)

Product Design (Skip to: Innovation – Students of Product Design Episode1)

Product Analysis and Specification/Evaluation

- Access FM (PDF)

Q

R

S

Sharpening a wood plane (Best sharpening tutorial I’ve ever seen)

Smart Materials (Prezi)

Strategies for innovation (PPT)

T

Tempering: After hardening, the metal is too brittle to be usable, so it needs to be tempered. Steel needs to get to about 600 degrees for tempering. Use the colour of the steel as a guide to its temperature, which is indicated by the steel being a blue colour. In order to be able to see that, the steel needs to have the black colour from the oil quench scrubbed off. Quench in oil.

U

V

Vertical Milling Machine (URL)

W

Woodwork – Beginners’ Hand Tool Course (Brilliant set of YouTube videos!)

Wood: Database

Wood: Database (L3)

Wood: Musical Money Box Presentation (OUTSTANDING pdf!)

Wood: Musical Money Box Presentation (EXCELLENT website!)

Wood: Musical Money Box Presentation (EXCELLENT powerpoint!)

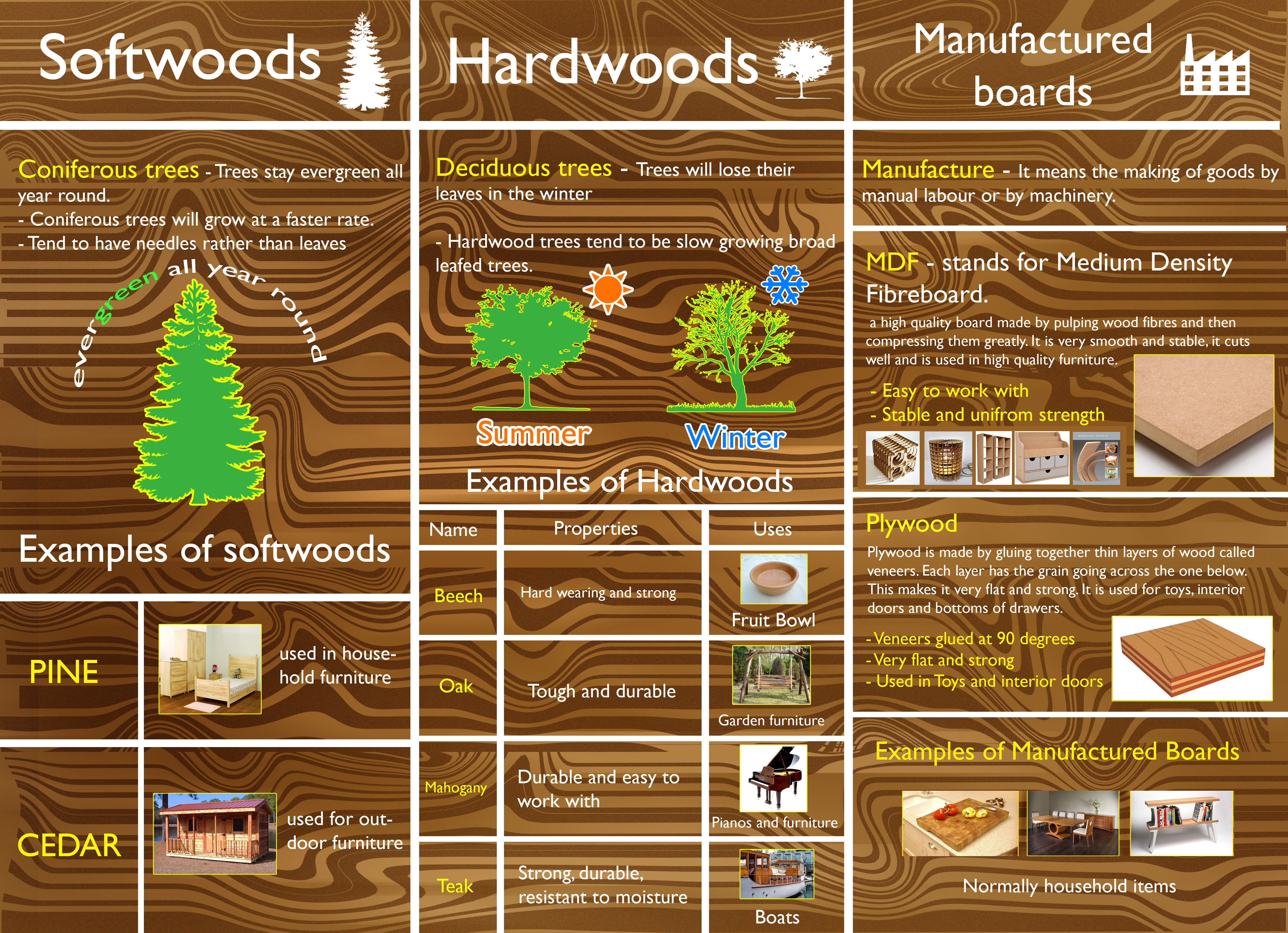

Wood: Timber

Wood (General)

- Print the following on A3:

Woodworking skills:

Good website…

http://www.mr-dt.com/

LikeLike

NOTE: fablabman is Jen Sean Wong

LikeLike

Mr DT- useful link http://www.mr-dt.com/

Possible addition?…

LikeLike

A useful website for DT and more.

http://www.wikihow.com/Main-Page

LikeLike

This is a useful site

LikeLike

http://www.woodworkbasics.com

LikeLike

A useful site is http://www.technologystudent.com/

LikeLike

Also Recommend these. http://www.mr-dt.com/ http://www.woodworkbasics.com/ Good for teaching Year 7’s, I think.

LikeLike

good website nice

LikeLike